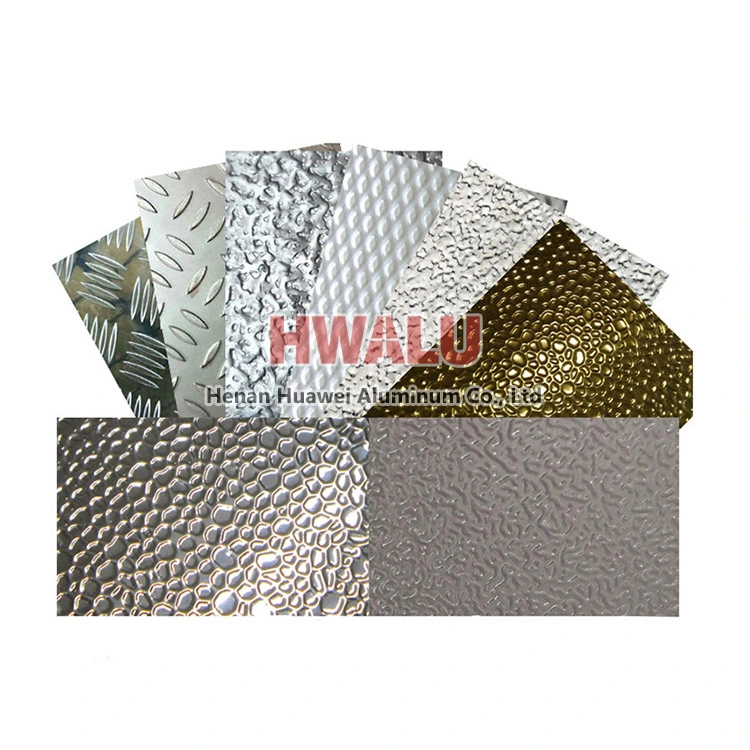

According to the alloy, it can be divided into 1000 series embossed aluminum sheet 2000 series embossed aluminum sheet 3000 series embossed aluminum sheet 4000 series embossed aluminum sheet 5000 series embossed aluminum sheet 6000 series embossed aluminum sheet 7000 series embossed aluminum sheet 8000 series embossed aluminum sheet Features of embossed aluminum sheet plate Antisli ...

Product Description of Embossed Aluminum for Refrigerator Product Name stucco embossed aluminum for refrigerator Alloy 1050,1060,1100,3003,3004 Temper H14,H16,H24 Thickness 0.2-0.8mm Width 100-1300mm Length Customed Surface treatment Mill finish, embossed(Coil&Sheet) MOQ 5MT General parameters of embossed aluminum technology for refrigerators T ...

Parameters of the embossed aluminum foil roll Alloy 1100\8011 Temper H22\0\H18 Thickness 0.04--0.25mm Width 200--1300mm Diameter 76\152 Color silver, black, gold, etc Surface treatment printed, coated, etc Custom pattern orange peel, star-struck emboss, etc What is an embossed aluminum foil roll? Aluminum foil shall be annealed and softened before embossi ...

Embossed aluminum sheet is also called stucco aluminum sheet. It is based on aluminum plate. After calendering, various beautiful patterns are formed on the surface of aluminum sheet. Therefore, it is called embossed aluminum sheet in the industry. This product is widely used and is common in product packaging and architectural decoration. Why embossed aluminum sheet is used in refrigerator liner and what advanta ...

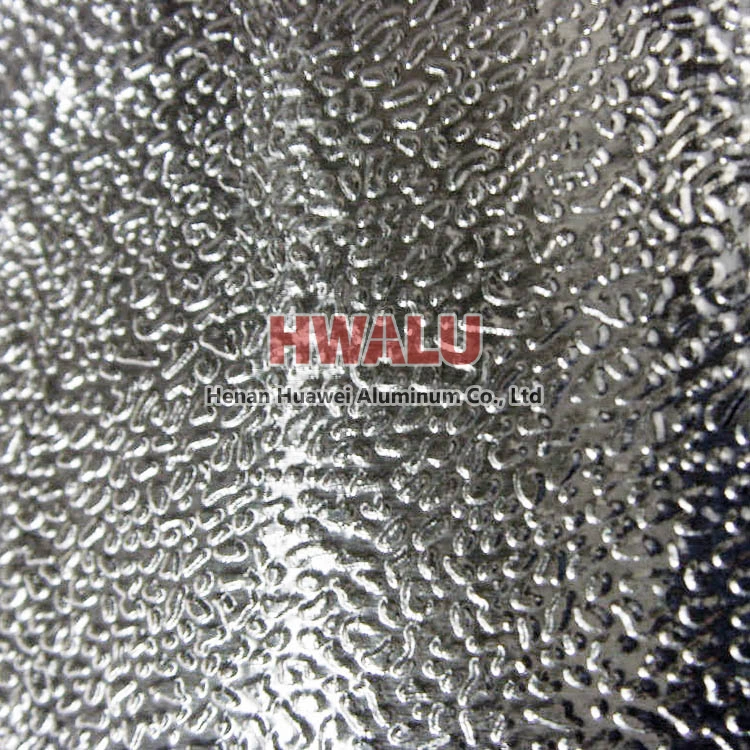

Due to embossed aluminum's high corrosion resistance, high thermal conductivity, high reflectivity and low emissivity, these products can successfully withstand continuous temperatures up to 650°C (1200° F) and reduce radiant heat by 90%. Easy to cut with tin scissors, simply fold over the square edge with a hammer and form the edge. Embossing offers unlimited design potential. Embossed patterns are eas ...

Parameters of 1xxx series embossed aluminum Alloys 1050, 1060, 1100, 1200 etc Temper Soft HO (h0), H11, H12, H13, H14, H15, H16, H17, H18, H19, H20, H21, H22, H23, H24, H25, H26, H27, H28, H29, H30, H31, H32, H33, H34, H35, H36, H37, H38, H39, H46, H48, H111, H112, H114, H116, H131, H321 etc According to the product type, it can be divided into 1000 series embossed aluminum sheet plate 1000 s ...

1. Aluminum has better heat transfer performance and ranks among the best among metals; 2. A dense oxide film can be formed on the surface of aluminum, which has good corrosion resistance; 3. The proportion of aluminum is relatively small, and the weight of the manufactured equipment is relatively light; 4. Embossing can increase the heat transfer area and improve the heat transfer efficiency. The e ...

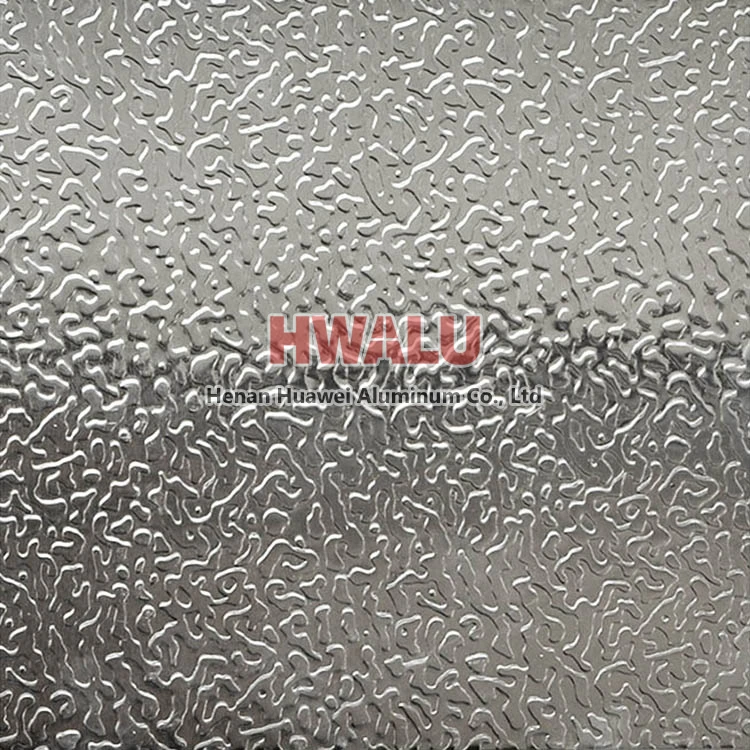

stucco aluminum coil also called stucco embossed aluminum coil Embossed aluminum coil, after the process of embossing, cutting, oxidation will form the surface with a dense layer of aluminum oxide protective film. And It has obvious below advantages such as acid-corrosion-resistance, long-lasting shine, beautiful patterns, anti-corrosion performance and stability, strong adhesion, impact resistance, non-toxic ...

Parameters Of 3xxx Series Embossed Aluminum Alloys: 3003, 3004 etc Temper Soft HO (h0), H11, H12, H13, H14, H15, H16, H17, H18, H19, H20, H21, H22, H23, H24, H25, H26, H27, H28, H29, H30, H31, H32, H33, H34, H35, H36, H37, H38, H39, H46, H48, H111, H112, H114, H116, H131, H321 etc According to the product type, it can be divided into 3000 series embossed aluminum sheet plate 3000 series embo ...

The concept of orange peel embossed aluminum Embossed aluminum coil/aluminum plate (patterned aluminum plate) is an aluminum product with a pattern formed on the surface after calendering on the basis of aluminum plate. There are mainly orange peel, diamond, bean pattern, Samsung, hemispherical and other patterns, which are commonly used in packaging, construction, curtain walls, refrigerators, air conditioners, ...